Gas Alarm Systems

With more than 30 years of unrivalled experience behind us, we confidently utilise our in-house expertise to deliver reliable, cost-effective gas detection solutions tailored to your industry’s specific gaseous hazards. Our extensive range of products is manufactured in strict compliance with British safety standards, providing you with complete peace of mind and unparalleled protection from asphyxiate, toxic, and flammable gases.

Services

We are able to offer our clients the choice of services to suit their needs.

Our Support ServicesOur Sectors

Gas Alarm Systems provide detection solutions to a host of industry sectors:

- Commercial

- Industrial

- Retail

- Leisure

- Production

- Energy

- Food Manufacture and Processing

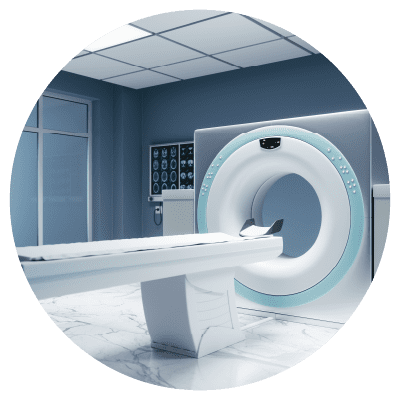

- Laboratory and Medical

- Marine

- Automotive

- Water Treatment

- Refrigerant

- Refuse

- Chemical Industry

Our Solutions

Natural Gas Detection Systems & Alarms

Natural Gas Detection Systems & AlarmsOur natural gas detection systems provide reliable early warning for toxic gases used in industries. With decades of experience in the industry, we confidently protect staff from colorless, odorless, and explosive gases. Trust us for complete peace of mind with our leak detectors and monitors.

Carbon Monoxide Gas Detection Systems & Alarms

Carbon Monoxide Gas Detection Systems & AlarmsAt Gas Alarms Systems, we’re experts in carbon monoxide gas detection. Our range of detectors and alarms work together to alert everyone about a gas leak promptly. Our detectors provide an effective warning system for workers in hazardous environments. We have a wide range of detectors to choose from, and our team of experts is always available to help you.

Carbon Dioxide Gas Detection Systems & Alarms

Carbon Dioxide Gas Detection Systems & AlarmsOur specialized products detect carbon dioxide, protecting you and your employees from this toxic gas. CO2 is usually present in low concentrations and is not harmful, but high concentrations can be dangerous. Our alarms and detectors are highly sensitive and can distinguish between safe and unsafe levels of CO2. They can help protect against headaches, confusion, loss of consciousness, and even death.

Methane Gas Detection Systems & Alarms

Methane Gas Detection Systems & AlarmsOur methane detectors are the most reliable solution to detect harmful levels of methane gas. They provide early warnings of dangerous concentrations, giving you and your staff enough time to take necessary action. With our detectors, you can be confident in keeping your staff and premises safe from any potential harm associated with methane gas.

Nationwide Coverage

Gas Alarms System is proud to offer a team of highly skilled gas detection engineers backed by the expertise of Protec Fire and Security Group Ltd. With this strong support, we confidently provide comprehensive nationwide coverage for unrivalled gas detection service and maintenance.

Our Products

Gas Alarm Systems supply a comprehensive range of fixed and portable gas detectors for commercial and industrial use

Market leaders In the procurement of gas detection solutions

- 30 Years of Experience

- Market Leading Experts

- Bespoke Detection Systems

- Tailor Made Solutions

Call us on 01423 862240 or email customerservice@gasalarmsystems.co.uk